Tin tức

Top 6 Steps to Better Beer

Sorting out the critical from the trivial is not easy. Some important aspects of homebrewing get relatively little press, while oceans of ink are spilled on less important aspects simply because a technical explanation of how they work is available.

This article willl give the top 6 most important steps to brewing better beer, in (at least roughly) their order of importance. Most steps are well-known, even to most beginners. But hopefully, by ordering their importance, it will spur beginning (and intermediate) brewers to think about their brewing process.

#1 Cleaning

There’s no getting away from it, the most important part of brewing is also the least glamorous — cleaning your equipment. Without sparkling clean equipment, there’s no way to sanitize it and hence no way to brew quality beer.

Everything in your brewery needs to be cleaned. Certainly any surface that touches wort or beer needs to be spotless, but so should other surfaces on equipment and your brewing environment. Otherwise, soil can be transferred from an unclean surface to clean equipment and then come in contact with wort or beer. Keep in mind that your hands touch many things during a brewday. If you’re going to handle a cleaned and sanitized piece of equipment after touching anything of suspect cleanliness, wash your hands before proceeding.

One of the biggest keys to making cleaning manageable is to clean everything immediately after use. It’s relatively easy to clean brewpots, fermenters or empty bottles before the “crud” on them has time to harden. Also cleaning immediately prevents the soil on your equipment from becoming a breeding ground for contaminating microorganisms, which brings us to . . .

#2 Sanitation

Wort (unfermented beer) is a rich growth medium for microorganisms. But, the only microorganism you want growing in it is brewers yeast. If bacteria or wild yeast begin growing in your wort or beer, sour, acetic, phenolic or other off flavors and aromas may result. Without proper sanitation, anything else you do on brewday is futile.

The most important pieces of advice a new brewer should learn about sanitation is to use sanitizers only after equipment is clean and only at their proper concentration — more isn’t better.

Finally, keep in mind that your beer is not equally prone to contamination throughout the process. Cool, aerated wort is a very good growth medium for a variety of microorganisms. Beer is less so. There are beer-spoiling organisms, but the alcohol content and low pH of finished beer are a partial shield against contamination.

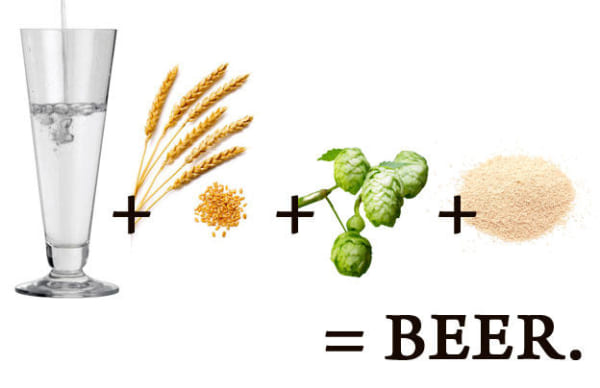

#3 Quality Ingredients

In many ways, brewing is like cooking. This is especially true when it comes to ingredients. You need fresh, quality ingredients to make good beer. So, it pays to review how to identify fresh ingredients.

#4 Proper and Stable Fermentation Temperature

If you pitch an adequate amount of yeast, the next most important factor is to ferment your beer in the yeast’s preferred temperature range and to keep the wort temperature (at least relatively) stable throughout the fermentation.

If the ambient temperature in your house isn’t suitable, some low-tech methods — such as covering a carboy with a wet T-shirt — allow for a small, though, reliable amount of cooling. Likewise, wrapping the carboy in a warm blanket helps the fermenter retain heat.

Slightly more high-tech solutions to temperature control include using a chest freezer with a thermostat on it or buying a fermenter with built in cooling.

#5 Avoid Excess Tannins

Fermentation is important, but you need to present the yeast with good wort to ferment. Making wort is relatively straightforward, but there are a few problems that can arise. One of the most common things that goes wrong when mashing, partial mashing or steeping grains is extracting too many tannins from the grain. If too many tannins end up in your beer, a drying, astringent mouthfeel results. When this happens, the most common culprit is sparging or rinsing the grains with too much water. You should mash with 1–2 quarts per pound (2.2–4.4 L per kg). If you are an extract brewer steeping grain, use 1–3 quarts per pound (2.2–6.7 L per kg).

But more importantly, do not oversparge or rinse your grains excessively. All-grain brewers can monitor the specific gravity of their final runnings and stop collecting wort when the gravity drops to 1.008. (Or, if you have pH meter, you can stop when the pH exceeds 5.8.) Extract brewers should just keep the rinse water limited to the same volume or less than they steeped with. And finally, keep the temperature of the sparge or rinse water under 170 °F (77 °C).

#6 Keep Oxygen Away

Yeast need oxygen when they are pitched in order to grow and ferment the wort properly. However, after they have been “fed,” you should strive to minimize your wort or beer’s exposure to oxygen. Exposure to oxygen while beer ages leads to papery or cardboard-like aromas in beer.

And, the presence of oxygen can spur the growth of some beer-spoiling organisms, like Acetobacter, which causes a vinegar-like character in beer contaminated with it. To avoid this, keep your buckets sealed and fermentation locks filled, rack your beer quietly and use a container without a lot of headspace for conditioning your beer. If you have a kegging system, you may also want to fill receiving vessels with CO2 before racking beer into them.

Tiếng Việt

Tiếng Việt